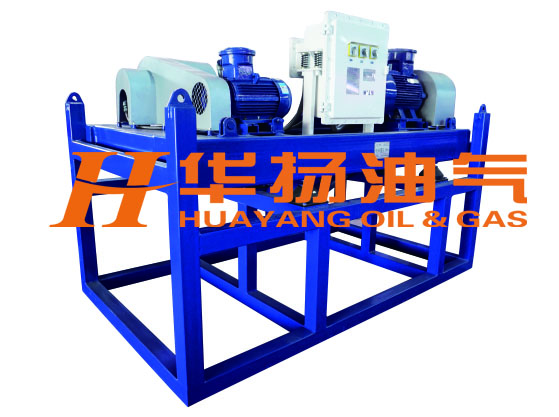

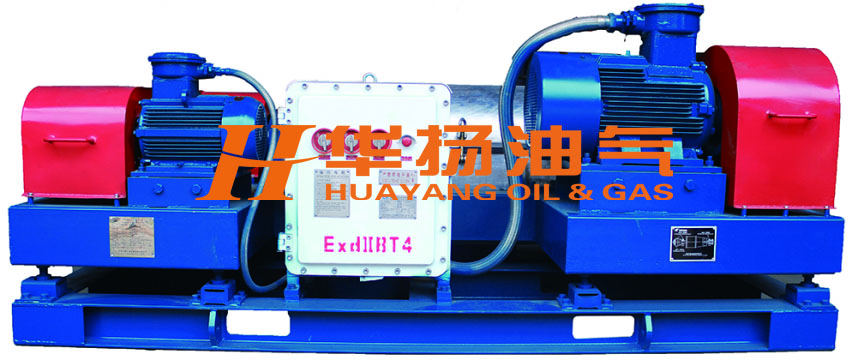

Centrifuge

| Model | HYLW600B-1 | HYLW450N-1 | HYLW450N-2 | HYLW355N-1 | HYLW355NB-1 |

|

Bowl Diameter |

600mm | 450mm | 450mm | 355mm | 355mm |

|

Bowl Length |

1500mm | 1000mm | 1250mm | 1250mm | 1250mm |

|

Bowl Speed |

2200r/min | 2200r/min | 3200r/min | 3200r/min | 0~3200r/min |

|

Treatment Capacity |

90㎥/h | 50㎥/h | 40㎥/h | 40㎥/h | |

| G-Force | 815 | 815 | 2035 | 2035 | 0~2035 |

| Separation point | 5~7μm | 5~7μm | 2~5μm | 2~7μm | |

|

Separation point |

40r/min | 40r/min | 30r/min | 30r/min | 0-30r/min |

|

Gear Box Ration |

35:1 | 57:1 | |||

|

Main Drive Motor |

55kw | 30kw | 37kw | 30kw | 37kw |

|

Back Drive Motor |

15kw | 7.5kw | 7.5kw | 7.5kw | 7.5kw |

|

EX Standard |

ExdIIBt4 / IECEX / A-TEX | ||||

| Wright | 4800kg | 2700kg | 3200kg | 2900kg | 3200kg |

|

Dimension |

2900×1900×1750mm | 2600×1860×1750mm | 2600×1860×1750mm | 2600×1620×1750mm | 2600×1620×1750mm |

Features and Benefits:

1.Adopt 2205 duplex stainless steel for the Cylindrical and Conical section,and centrifugal casting process.

2.The rest of bowl assy are all SS316L.

3.Spiral conveyor is protected by wear-resistant alloy plate,long service life and east to maintain and replace.

4.Branch mouth of conveyor and solids outlet of bowl are both protected by wear-resistant alloy sheath which is easy to replace,lengthen the usage life,and maintenance cycle.

5.Bowl assy is protected by dismantled support during transportation,prevent the damage to bearings in the transportation.

6.Adopt original packing imported SKF and NSK bearings to improve the machines stability and long service life.

7.Adopt variable frequency control,and make user be convenient to adjust rotation speed anytime,meet different working situations.

8.Adopt the electrical components of Schneider or Siemens,select the current overload protection and mechanical limit switch double protection.

1.Adopt 2205 duplex stainless steel for the Cylindrical and Conical section,and centrifugal casting process.

2.The rest of bowl assy are all SS316L.

3.Spiral conveyor is protected by wear-resistant alloy plate,long service life and east to maintain and replace.

4.Branch mouth of conveyor and solids outlet of bowl are both protected by wear-resistant alloy sheath which is easy to replace,lengthen the usage life,and maintenance cycle.

5.Bowl assy is protected by dismantled support during transportation,prevent the damage to bearings in the transportation.

6.Adopt original packing imported SKF and NSK bearings to improve the machines stability and long service life.

7.Adopt variable frequency control,and make user be convenient to adjust rotation speed anytime,meet different working situations.

8.Adopt the electrical components of Schneider or Siemens,select the current overload protection and mechanical limit switch double protection.